UFA offers a wide variety of chain and cable which can make it difficult to find the perfect one for the job. All of the chain and cable products that we offer have unique strengths and weaknesses based on their material, construction and other characteristics. To help you decide which chain or cable is the best suited to your needs, we have put together this guide that will simplify the process and help you select a product that will get the job done.

CHAIN TYPE OVERVIEW

CHAIN GRADE & SAFE WORKING LOAD

CHAIN PROPERTIES AND APPLICATIONS

CABLE OVERVIEW

| Chain Type/ Style |

Grade | Coating/ Finish |

Available Sizes | Applications |

|---|---|---|---|---|

| Machine | N/A | Zinc | #2 | Guard rails, Tailgate chains, Door chain, Playground equipment |

| Machine Twist | N/A | Zinc | #4, 2/0 | Pet chains, Playground equipment |

| Passing Link | N/A | Zinc | 2/0 | Gates, Farm equipment |

| Proof Coil | 30 | Zinc | 1/8”, 3/16”, 1/4”, 5/16”, 3/8” | Pulling stumps, Truck tailgates, Guard rails |

| Proof Coil | 30 | Steel | 3/8” | Pulling stumps, Truck tailgates, Guard rails |

| Proof Coil | 30 | Galvanized | 1/4”, 5/16”, 3/8” | Pulling stumps, Truck tailgates, Guard rails |

| Proof Coil | 43 | Zinc | 1/4”, 5/16”, 3/8” | Pulling stumps, Truck tailgates, Guard rails |

| Proof Coil | 70 | Zinc | 1/4” | Pulling stumps, Truck tailgates, Guard rails |

| Sash | N/A | Zinc | #35 | Counterbalance chain for Double-hung windows, Arc lamps, Pet chains |

| Transport | 70 | Steel | 5/16”, 3/8” | Load binding in the Trucking industry |

What Does the Grade of a Chain Mean?

The grade of a chain refers to its tensile strength. The higher the grade, the stronger the chain will be.

What is Safe Working Load?

The safe working load of a chain is the maximum working load designated by the manufacturer. It represents a load that is less than the minimum load that would make a chain fail or break to ensure the user's safety when using the product. It is calculated by dividing the load at which the chain would fail by a certain safety factor specified by the manufacturer.

*Please see the specifications of each rope product for its safe working load.

Machine Chain

Made of low carbon steel, this chain is electronically welded and is not heat-treated. It has shorter links that make it very flexible

Pros: Greater flexibility than other general use chain.

Cons: Not intended for heavy weight loads.

Common Uses: Guard rails, tailgate chains, door chain, playground equipment.

Machine Twist Chain

Made of low carbon steel, this chain is electronically welded and is not heat-treated. It has shorter links that make it very flexible. Links are twisted to allow chain to lay flat.

Pros: Will lay flat unlike other styles of chain.

Cons: Not intended for heavy weight loads.

Common Uses: Pet chains, playground equipment.

Passing Link Chain

Made of low carbon steel, this chain is electronically welded and is not heat-treated. A general utility chain with a wide link design that allows the links to pass through one another which reduces the chance of tangling and kinking.

Pros: Less chance of kinks or tangling.

Cons: Not intended for heavy-duty use.

Common Uses: Gates, farm equipment.

Proof Coil Chain

Excellent general purpose, low carbon steel, utility chain

Pros: Cost effective, general purpose chain.

Cons: Lower strength than higher grade chain.

Common Uses: Pulling stumps, truck tailgates, guard rails.

Sash Chain

Stamped, flat-link chain that runs smoothly over pulleys. It is made from low carbon steel and is not heat treated.

Pros: Lays flat and runs smoothly over pulleys.

Cons: Low strength chain.

Common Uses: Counterbalance chain for double hung windows, arc lamps, pet chains.

Transport Chain

Made of heat-treated, high carbon steel, this chain offers superior strength and wear resistance. It is lightweight despite its strength and easy to handle.

Pros: Superior strength and wear resistance.

Cons: More expensive than lower grade chain.

Common Uses: Load binding in the trucking industry.

| Construction | Plastic Coated? | Available Sizes | Applications |

|---|---|---|---|

| 7x7 | Yes | 3/32" | Tensioning, security cables, cable railings |

| No | 3/16" | Tensioning, security cables, cable railings | |

| 7x19 | No | 1/8”, 1/4", 5/16”, 3/8” | General utility, security cables, winch cables |

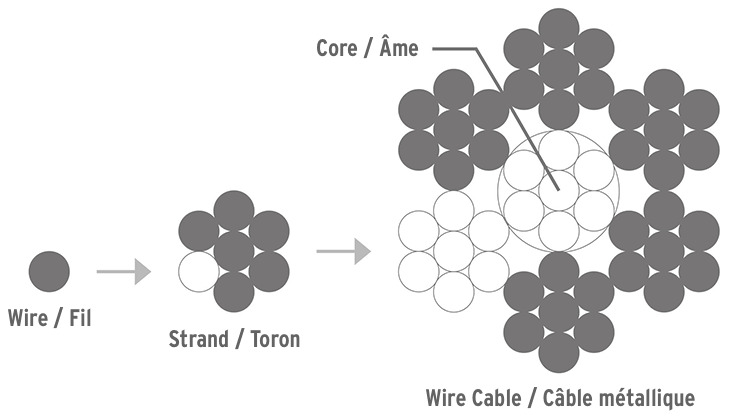

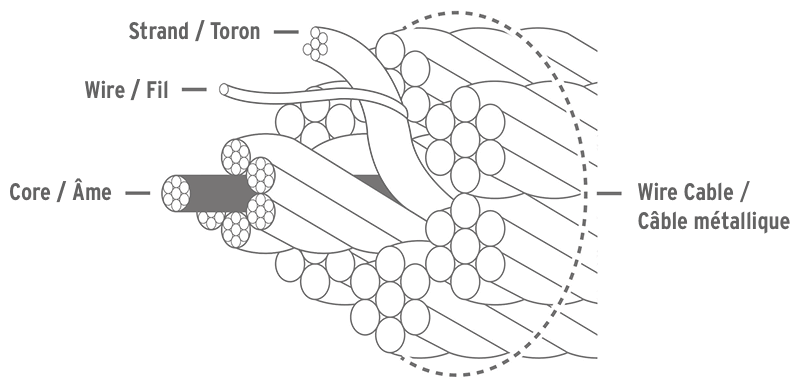

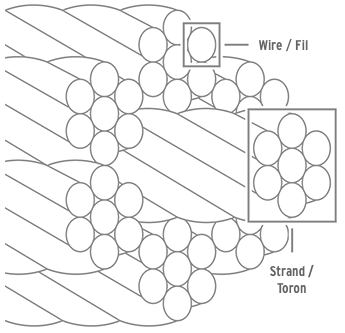

Cable Construction

Cable is constructed of special strength similar size wire wound together to make a strand. These individual strands are wound together to make a cable or wire rope.

Cable is specified by the number of strands, times the number of wires in each strand.

For example, 7 x 19 means that the cable has seven (7) strands and there are nineteen (19) wires in each strand.

Cable Materials

The material of the individual wires that make up a strand will affect the properties of your cable.

Galvanized: Slightly stronger than stainless steel, but less corrosion resistant.

Stainless Steel: Similar in strength to galvanized steel and corrosion resistant. More expensive

Galvanized Plastic Coated: Superior protection against the elements, can last longer than a non-coated cable. Does not offer good abrasion resistance.

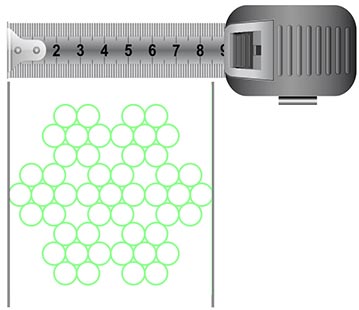

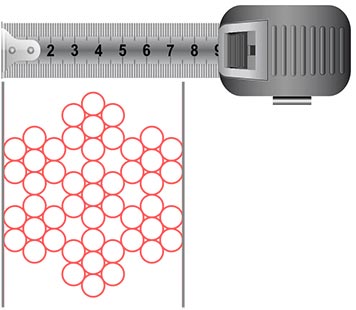

How to Measure Cable Diameter

Correct

Incorrect

7X7 Cable

Cable is made up of 7 strands. Each strand consists of 7 wires.

Pros: Cost effective.

Cons: Rigid in larger diameters.

Common Uses: Tensioning, security cables, cable railings.

7X19 Cable

Cable is made up of 7 strands. Each strand consists of 19 wires.

Pros: Superior strength and flexibility.

Cons: Rigid in larger diameters.

Common Uses: Tensioning, security cables, cable railings.

- Do not exceed safe working load.

- Do not use for hoisting or overhead lifting

- Do not use if rope is visibly worn or distorted.

- Misuse can result in serious injury, property damage or death.